Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

Have you ever considered the dangers of working at heights? Construction hoists are essential for lifting materials, but they pose significant risks.

Safety is crucial in construction environments, where falls can lead to severe injuries.

In this article, we’ll explore what anti-fall safety devices are and why they are vital for protecting workers.

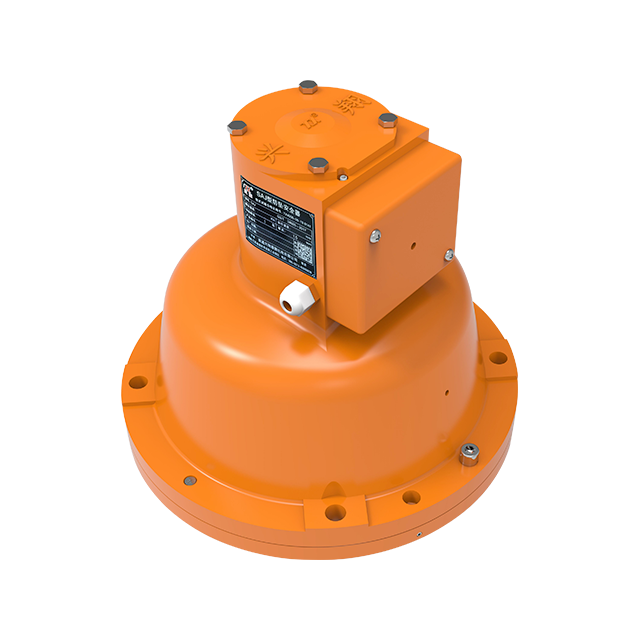

Anti-fall safety devices are crucial tools designed to prevent falls from construction hoists. These devices work by detecting abnormal movement and applying brakes to stop the descent of the hoist.

Their primary purpose is to safeguard workers and materials on construction sites. By ensuring stability, they minimize the risk of accidents, which can have devastating consequences.

Construction sites are inherently risky. Did you know that falls are among the leading causes of injuries in the industry? According to recent statistics, about 36% of construction fatalities are due to falls. This highlights the urgent need for effective safety measures.

● Injuries: Falls can lead to serious injuries, including fractures, concussions, and even fatalities.

● Financial Impact: Accidents can result in costly medical bills, legal fees, and increased insurance premiums.

● Project Delays: Injuries can halt work, causing delays and affecting project timelines.

In many regions, regulatory bodies mandate the use of anti-fall safety devices on construction sites. These regulations aim to protect workers and ensure compliance with safety standards. For example:

● OSHA (Occupational Safety and Health Administration) sets forth guidelines to minimize fall hazards.

● Local building codes often require specific safety measures for hoists.

Regulatory Body | Requirement |

OSHA | Must use anti-fall devices on hoists |

Local Codes | Compliance with safety standards |

By adhering to these regulations, construction companies can create safer work environments. Implementing anti-fall safety devices not only protects workers but also helps businesses avoid legal complications and financial losses.

Anti-fall safety devices are engineered to protect workers from falls while using construction hoists. They utilize various mechanisms to ensure safety. Here’s a closer look at how they function:

● Detection Mechanisms: These devices monitor the speed and movement of the hoist. If they detect an abnormal descent, they spring into action.

● Braking Systems: Once an abnormality is detected, the device applies a braking force. This stops the hoist quickly, preventing a fall.

● Speed Monitoring: Constantly checks the descent speed of the hoist.

● Emergency Braking: Engages brakes immediately if descent exceeds safe limits.

● Alarm Systems: Some devices include alarms to alert operators of malfunctions.

Function | Description |

Speed Monitoring | Ensures descent speed remains within safe limits |

Emergency Braking | Engages brakes to stop rapid descents |

Alarm Systems | Notifies operators of any issues or malfunctions |

Reliable anti-fall safety devices play a crucial role in preventing accidents on construction sites. For instance, in a recent high-rise project, a malfunctioning hoist nearly led to a serious accident. Thankfully, the installed anti-fall device activated, stopping the hoist just in time.

● Case Study 1: A construction site in New York City reported zero fall-related injuries after implementing advanced anti-fall safety devices.

● Case Study 2: In a Chicago skyscraper project, a device prevented a potentially fatal fall, showcasing its effectiveness.

In high-rise construction, safety is paramount. Anti-fall safety devices ensure that workers can operate hoists confidently. They help maintain productivity while safeguarding lives.

● Increased Worker Confidence: Knowing that reliable safety devices are in place allows workers to focus on their tasks.

● Compliance with Safety Standards: These devices help companies meet regulatory requirements, reducing the risk of fines and legal issues.

By investing in high-quality anti-fall safety devices, construction companies not only protect their workers but also enhance overall project safety.

Centrifugal-based anti-fall devices use the principles of centrifugal force to enhance safety. When a hoist descends too quickly, the device detects this rapid movement. Here’s how it works:

● Mechanism of Action: As the hoist accelerates, centrifugal force activates the braking system. This stops the descent almost instantly.

● Effectiveness: These devices are known for their reliability. They can react faster than traditional systems, significantly reducing the risk of falls.

● Centrifugal Devices: Typically respond within 0.5 seconds.

● Competitor Products: Many standard devices take 1-2 seconds to react.

Device Type | Response Time |

Centrifugal-Based | 0.5 seconds |

Traditional Devices | 1-2 seconds |

Rope-tension monitoring devices are essential for ensuring that hoist ropes maintain proper tension. They work by constantly checking the tension levels in the ropes.

● Monitoring Mechanism: These devices use sensors to measure rope tension. If tension drops below safe levels, the system activates a backup braking mechanism.

● Backup Braking System Activation: When the device detects inadequate tension, it engages brakes to prevent accidents.

Maintaining proper tension in hoist ropes is vital. Insufficient tension can lead to:

● Rope Slippage: This can cause the load to fall.

● Increased Wear: Loose ropes wear out faster, leading to potential failures.

Impact-detection and arrest systems utilize advanced technology to prevent falls. They incorporate various detection methods, such as accelerometers and shock sensors.

● Detection Methods: These systems monitor sudden changes in movement. If an impact is detected, they spring into action.

● Engagement Mechanism: Upon detecting a fall, the system activates brakes to stop the descent immediately.

● Accelerometers: Measure changes in speed and direction.

● Shock Sensors: Detect impacts and trigger safety mechanisms.

Technology | Function |

Accelerometers | Monitor speed changes |

Shock Sensors | Detect impacts |

These advanced systems provide an extra layer of safety, ensuring that workers are protected during high-risk operations. By implementing these various types of anti-fall safety devices, construction sites can significantly reduce the risk of accidents and enhance overall safety.

When evaluating anti-fall safety devices, performance under various environmental conditions is crucial. Factors such as temperature, humidity, and corrosion can significantly impact functionality.

● Temperature: Devices need to operate effectively in extreme heat or cold. For example, some centrifugal-based devices perform well in temperatures ranging from -20°C to 50°C, while others may falter.

● Humidity: High humidity can affect sensor accuracy. Devices designed for marine environments often include protective coatings to ensure reliability.

● Case Study 1: A construction site in Florida used rope-tension monitoring devices. Despite high humidity, these devices maintained consistent performance, preventing accidents.

● Case Study 2: In a cold climate, a project in Canada found that their impact-detection systems functioned reliably even at sub-zero temperatures.

Using corrosion-resistant materials enhances durability. Devices made from stainless steel or coated with protective layers show better performance in harsh conditions.

Condition | Device Type | Performance |

High Humidity | Rope-Tension Monitors | Excellent |

Extreme Cold | Impact-Detection Systems | Reliable |

Coastal Environments | Centrifugal Devices | Corrosion-Proof |

Installation processes vary among different anti-fall safety devices. Understanding these can help in making informed choices.

● Installation Overview: Some devices require complex setups, while others are designed for quick installation. For instance, modular designs allow for easier assembly and disassembly.

● Low-Maintenance Devices: Many modern systems are designed to require minimal upkeep. They often include features like self-diagnostics.

● High-Maintenance Devices: Older models may need frequent inspections and part replacements, which can increase overall costs.

Device Type | Installation Complexity | Maintenance Frequency |

Modular Systems | Easy | Low |

Traditional Systems | Complex | High |

When considering anti-fall safety devices, cost-effectiveness is a major factor. Prices can vary widely, so understanding the long-term implications is key.

● Price Range: Basic devices may start around $500, while advanced systems can exceed $5,000.

Investing in higher-quality devices can lead to savings over time. Features like remote monitoring and self-diagnostic capabilities reduce maintenance costs and enhance reliability.

● Remote Monitoring: Allows for real-time performance tracking, reducing the need for frequent manual checks.

● Self-Diagnostic Capabilities: Help identify issues before they become serious problems, saving on repair costs.

Feature | Initial Cost | Long-Term Savings |

Remote Monitoring | Higher | Significant |

Self-Diagnostic Systems | Moderate | Moderate |

By comparing these aspects, it becomes clear how different anti-fall safety devices stack up against each other. This knowledge aids in making informed decisions for construction safety.

Choosing the right anti-fall safety device is crucial for ensuring worker safety. Here are some key factors to consider:

● Compliance with Safety Standards: Ensure the device meets local and national safety regulations. This is non-negotiable for maintaining safety on-site.

● Site-Specific Conditions: Evaluate the specific conditions of your construction site. Factors such as height, type of work, and environmental conditions can influence your choice.

● Heavy-Duty Sites: For high-risk areas, opt for robust devices like centrifugal-based systems.

● Low-Height Work: In less risky scenarios, simpler devices may suffice, such as basic rope-tension monitors.

Criteria | Importance | Recommended Device |

Compliance | Legal and safety reasons | All devices must meet standards |

Environmental Conditions | Performance reliability | Corrosion-resistant materials |

Site Height | Risk assessment | Centrifugal or impact-detection systems |

Maintaining anti-fall safety devices is essential. Here’s how to do it effectively:

● Inspection Schedules: Regular inspections should occur at least once a month. After any significant incident, conduct an immediate inspection.

● Visual Checks: Look for signs of wear or damage.

● Functionality Tests: Ensure all mechanisms operate smoothly.

● Record Keeping: Document findings and maintenance actions. This is vital for safety compliance.

Inspection Item | Frequency | Notes |

Visual Inspection | Monthly | Check for damage or corrosion |

Functionality Test | Monthly | Test brakes and sensors |

Maintenance Records | Ongoing | Keep detailed logs for compliance |

Training is a cornerstone of effective anti-fall safety device implementation. Here’s why it matters:

● Importance of Training: Proper training ensures that operators understand how to use devices correctly. This reduces the risk of accidents significantly.

● On-Site Training: Conduct hands-on training sessions for all operators.

● Certification Courses: Encourage participation in recognized safety programs.

Awareness of potential hazards is critical. Operators should be trained to recognize unsafe conditions and act accordingly. This proactive approach can prevent many accidents.

Training Aspect | Focus | Outcome |

Hands-On Training | Device operation | Increased familiarity |

Safety Programs | Hazard recognition | Enhanced awareness and prevention |

Regular Refresher Courses | Updates on best practices | Continuous improvement in safety |

By following these best practices, construction sites can effectively implement anti-fall safety devices, ensuring a safer work environment for everyone involved.

The landscape of anti-fall safety devices is evolving rapidly. Emerging technologies are reshaping how we approach safety on construction sites.

● AI and IoT Integration: Artificial Intelligence (AI) and the Internet of Things (IoT) are making safety devices smarter. These technologies allow devices to analyze data in real-time, improving response times during emergencies.

● Smart Technologies: Devices equipped with sensors can monitor conditions continuously. For example, they can detect falls instantly and send alerts to supervisors.

● Data Analytics: By collecting and analyzing data, these devices can identify patterns and potential risks, leading to proactive safety measures.

Technology | Functionality | Impact on Safety |

AI-Powered Sensors | Real-time analysis | Faster response to incidents |

IoT Connectivity | Remote monitoring | Continuous oversight of safety |

Data Analytics | Risk identification | Proactive safety improvements |

As technology advances, so do regulations surrounding anti-fall safety devices. Staying informed about these changes is essential.

● Upcoming Regulations: New regulations are on the horizon, focusing on stricter safety standards for equipment. These changes may require manufacturers to innovate their designs.

● Staying Updated: Companies must keep abreast of industry standards to ensure compliance. Regular training and updates can help maintain safety protocols.

● Design Innovations: Regulatory changes may push manufacturers to develop devices that are not only safer but also more user-friendly. Features like easy installation and maintenance could become standard.

Regulatory Aspect | Expected Changes | Effect on Devices |

Stricter Safety Standards | Enhanced testing | Improved reliability and safety |

Compliance Requirements | Regular audits | Increased focus on maintenance |

Design Innovations | User-friendly features | Better usability and efficiency |

By understanding these future trends, stakeholders can better prepare for the evolving landscape of anti-fall safety devices. Embracing technology and staying compliant will play a crucial role in enhancing safety on construction sites.

Construction hoist anti-fall safety devices are crucial for worker safety. They help prevent accidents and save lives on construction sites.

Prioritizing safety should be a top concern for everyone involved. We encourage readers to implement reliable anti-fall safety devices in their practices. Ensuring safety is not just a regulation; it’s a responsibility.

A: Common types include safety harnesses, guardrails, safety nets, and personal fall arrest systems.

A: Inspect anti-fall safety devices at least once a month, or after any significant incident.

A: Immediately stop using the device, report the failure, and conduct a thorough inspection.

A: Yes, regulations vary by location but generally include safety standards from organizations like OSHA.

A: Stay updated on regulations, conduct regular training, and perform routine inspections of safety devices.

A: High-quality devices enhance safety, reduce accident rates, and can lower insurance costs over time.