Views: 0 Author: Site Editor Publish Time: 2025-08-27 Origin: Site

Have you ever wondered how workers stay safe on suspended platforms? These platforms are crucial in construction and maintenance, allowing access to high places. However, without proper safety locks, the risks increase dramatically.

In this post, we’ll discuss why safety locks are essential for suspended platform safety. You’ll learn about their functions and how they protect workers from potential hazards.

A suspended platform is a temporary structure used to provide access to high or hard-to-reach areas. These platforms are essential in various industries, particularly in construction and maintenance. They allow workers to perform tasks safely while elevated, reducing the need for scaffolding.

Common Applications:

● Construction: For building facades and installing windows.

● Maintenance: Cleaning and repairing tall buildings.

● Painting: Accessing high ceilings and structures.

Suspended platforms come in various types, each designed for specific load capacities and uses. Here’s a quick overview:

Load Capacity | Common Uses |

500 kg | Light maintenance tasks |

630 kg | Standard construction work |

800 kg | Heavy-duty applications |

1000 kg | Industrial projects |

Materials Used:

● Hot-galvanized Steel: Offers durability and corrosion resistance.

● Aluminum Alloy: Lightweight and easy to maneuver.

Standard Sizes:

● Platforms typically range from 5m x 0.69m x 1.18m to 7.5m x 0.69m x 1.18m.

Suspended platforms consist of several essential components, each contributing to their functionality and safety.

Essential Components:

● Electric Hoists: These lift and lower the platform smoothly.

● Steel Wire Ropes: Provide the necessary strength to support the platform.

Lifting Mechanisms:

● Power specifications can vary, with common setups being:

○ 1.5 kW x 2

○ 1.8 kW x 2

○ 2.2 kW x 2

Working Heights and Load-Bearing Capabilities:

Suspended platforms can reach impressive heights, often up to 200 meters. This capability makes them invaluable for high-rise construction and maintenance tasks.

By understanding the structure and functionality of suspended platforms, we can better appreciate the importance of safety locks. These locks play a crucial role in preventing accidents and ensuring worker safety during elevated tasks.

Suspended platforms present several risks that can lead to serious accidents.

Key Hazards Include:

● Falls: Workers may fall due to improper securing of the platform or equipment failure. This is one of the leading causes of injuries.

● Equipment Failure: Mechanical issues, such as malfunctioning safety locks or hoists, can result in catastrophic failures.

Preventive Measures:

● Regular inspections can help identify potential issues before they lead to accidents.

● Proper training for workers on safety protocols is essential.

Understanding the statistics surrounding suspended platform accidents can highlight the importance of safety measures.

Accident Statistics:

● According to industry reports, approximately 60% of accidents involve falls from suspended platforms.

● Equipment failure accounts for about 25% of incidents, emphasizing the need for reliable safety locks.

Visual Representation:

Type of Accident | Percentage |

Falls | 60% |

Equipment Failure | 25% |

Other | 15% |

These numbers underscore the critical need for effective safety measures, including the use of safety locks.

Safety devices play a crucial role in ensuring the safety of suspended platforms.

Common Safety Devices Include:

● Safety Locks: These prevent accidental descent and keep the platform securely in place.

● Guardrails: Installed around the platform, they provide an additional barrier against falls.

● Emergency Stop Buttons: These allow workers to halt operations instantly in case of an emergency.

● Load Sensors: They monitor the weight on the platform, preventing overload situations.

Visual Representation:

Safety Device | Function |

Safety Locks | Prevent accidental descent |

Guardrails | Provide barriers against falls |

Emergency Stop Buttons | Allow immediate operation halting |

Load Sensors | Monitor platform weight |

Integrating various safety features is essential for enhancing overall safety.

When multiple devices work together, they create a comprehensive safety system.

Benefits of Integration:

● Redundancy: If one device fails, others can still provide protection.

● Increased Confidence: Workers feel safer knowing multiple systems are in place.

● Enhanced Compliance: Meeting safety regulations becomes easier when using integrated systems.

Key Takeaway: Using a combination of safety devices significantly reduces risks associated with suspended platforms, making it vital for all operations.

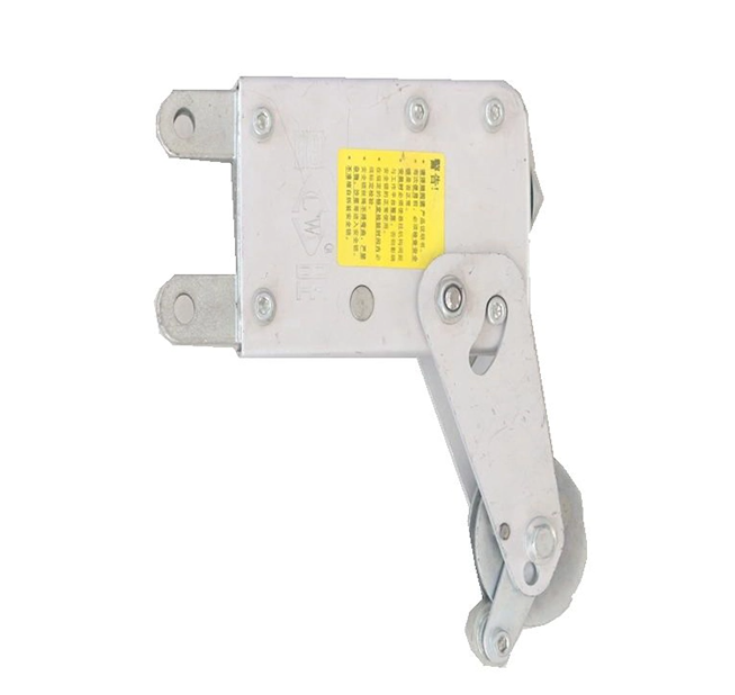

Safety locks are essential components in suspended platforms.

These devices serve a critical purpose: they prevent accidental descent.

Key Functions Include:

● Securing the Platform: They ensure the platform remains stable and secure while in use.

● Preventing Falls: By locking the platform in place, they significantly reduce the risk of falls.

● Enhancing Worker Safety: Safety locks are vital for protecting workers during operations at height.

Understanding how safety locks operate is crucial for recognizing their importance.

Operating Principles:

1. Mechanical Engagement: When the platform is raised, safety locks engage automatically, securing it in position.

2. Release Mechanism: To lower the platform, operators must manually release the locks, ensuring they are ready for safe descent.

3. Fail-Safe Features: Many locks include fail-safe mechanisms, which activate if there’s a malfunction, providing an extra layer of security.

Visual Representation:

Feature | Description |

Mechanical Engagement | Locks engage automatically when raised |

Release Mechanism | Manual release required for descent |

Fail-Safe Features | Activate during malfunctions |

These principles ensure safety locks function effectively, making them indispensable for suspended platforms.

Safety locks are designed to engage automatically during emergencies.

Critical Situations Include:

● Wire Rope Breakage: If the wire rope fails, safety locks activate to secure the platform.

● Platform Tilt: In case of an unexpected tilt, these locks engage to stabilize the platform and prevent accidents.

This automatic response is vital for ensuring immediate safety, minimizing the risk of falls.

One of the primary functions of safety locks is to prevent free-fall incidents.

How They Protect Workers:

● Immediate Engagement: When a malfunction occurs, locks engage instantly, stopping the platform from descending.

● Enhanced Safety: This feature provides peace of mind for workers operating at heights, knowing they are protected.

Key Benefits:

● Reduces the likelihood of severe injuries.

● Builds trust in the safety systems in place.

Safety locks come with various features that enhance their effectiveness.

Notable Additional Features:

● Manual Locking: Some systems allow for manual locking, giving operators more control.

● Material Durability: High-quality materials ensure long-lasting performance, even in harsh conditions.

Visual Representation:

Feature | Description |

Automatic Locking | Engages during emergencies |

Manual Locking | Provides operator control |

Material Durability | Ensures long-lasting performance |

These functions make safety locks a crucial component for the safety of suspended platforms.

Investing in high-quality safety locks offers numerous benefits.

Enhanced Impact Resistance:

● These locks withstand significant forces without failure.

Wear-Resistance:

● They maintain functionality over time, even in demanding conditions.

Compatibility:

● High-quality locks fit various suspended platform designs, making them versatile.

Long Service Life:

● Reliable performance in harsh environments ensures worker safety for years.

The materials used in safety locks significantly affect their performance.

Materials Used:

● Special Stainless Steel: Often combined with powder coating for added protection.

Benefits:

● Toughness: These materials resist deformation under stress.

● Corrosion Resistance: They withstand environmental factors, ensuring longevity.

Safety locks play a critical role during emergencies.

Detection of Rapid Descents:

● Advanced locks can sense quick drops and engage automatically.

Importance in Emergency Scenarios:

● In situations where every second counts, safety locks provide essential protection, preventing potential falls and injuries.

By understanding the importance and functionality of safety locks, we can appreciate their vital role in ensuring the safety of workers on suspended platforms.

The market for safety locks is diverse, featuring products from various manufacturers. Each brand offers unique locking mechanisms and sensitivity levels.

Comparison of Safety Locks:

● Manufacturer A: Utilizes a dual-locking system that engages quickly.

● Manufacturer B: Features a single-lock mechanism but boasts higher sensitivity.

● Manufacturer C: Offers a customizable locking sensitivity, allowing for tailored safety solutions.

Variations in Locking Mechanisms:

● Some locks use mechanical systems, while others rely on electronic sensors. This variety means users can choose based on their specific needs.

Recent advancements in safety lock technology enhance their effectiveness and reliability.

Advanced Monitoring Features:

● Integrity Checks: These systems regularly assess the lock's condition, ensuring it operates correctly.

● Alarms: Some locks come equipped with alarms that trigger during a malfunction or when thresholds are breached.

Integration with Other Safety Systems:

● Emergency stops can now work in tandem with safety locks. This integration creates a comprehensive safety network.

Enhanced Sensitivity and Improved Locking Mechanisms:

● Newer models feature better sensitivity, allowing them to detect even slight movements. This ensures immediate response in critical situations.

Certain safety locks stand out due to their unique features and materials.

Wider Locking Angle Range:

● Some locks can accommodate a broader range of angles, making them more versatile for different platform setups.

Sensitivity to Platform Tilts:

● Advanced locks quickly react to platform tilts, providing an extra layer of safety.

Use of Advanced Materials:

● High-quality materials enhance durability, ensuring that locks perform reliably over time, even in tough conditions.

The competition among safety locks drives innovation, leading to safer and more reliable options for suspended platforms. By exploring these products, users can find the best fit for their needs.

Proper installation of safety locks is crucial for ensuring the safety of suspended platforms.

Installation Techniques:

● Follow Manufacturer Instructions: Always adhere to the specific guidelines provided by the manufacturer. This ensures optimal performance.

● Secure Mounting: Ensure locks are mounted securely to prevent any movement during operation.

Importance of Professional Installation:

● Hiring a professional can prevent mistakes that might compromise safety. Experts understand the nuances of installation better than anyone.

Regular Inspections:

● Schedule routine inspections to catch any potential issues early. Regular checks can identify wear and tear before they become serious problems.

Maintaining safety locks is vital for their longevity and effectiveness.

Routine Checks:

● Weekly Inspections: Look for any signs of damage or wear. This includes checking for rust, cracks, or loose fittings.

● Maintenance Schedules: Develop a maintenance schedule based on usage. More frequent use may require more regular checks.

Signs of Wear:

● Visual Indicators: Look for discoloration, deformation, or unusual noises when operating the lock.

● When to Replace: If any signs of significant wear are present, it's time to replace the lock. Don’t wait for a malfunction to occur.

Educating workers about safety locks is essential for maximizing their effectiveness.

Importance of Training:

● Workers should understand how safety locks function and their critical role in preventing accidents. Providing hands-on training can enhance their understanding.

Creating Awareness:

● Discuss the risks associated with suspended platforms openly. Regular safety meetings can reinforce the importance of using safety locks correctly.

Safety Measures:

● Encourage a culture where workers feel comfortable reporting issues. This proactive approach can lead to a safer working environment.

By following these best practices, we can significantly enhance the safety of suspended platforms. Proper installation, maintenance, and training are key components in protecting workers and ensuring effective operation.

Safety locks are vital for ensuring the safety of suspended platforms. They prevent accidents and protect workers effectively.

Employers must prioritize safety measures, including proper installation and maintenance of these locks.

Staying informed about safety innovations is essential for everyone in the industry. Together, we can enhance safety standards and protect lives.

A: Common causes include equipment failure, improper installation, and lack of maintenance.

A: Safety locks should be inspected regularly, ideally weekly, and more frequently based on usage.

A: Immediately report the issue and cease operations until the lock is repaired or replaced.