Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

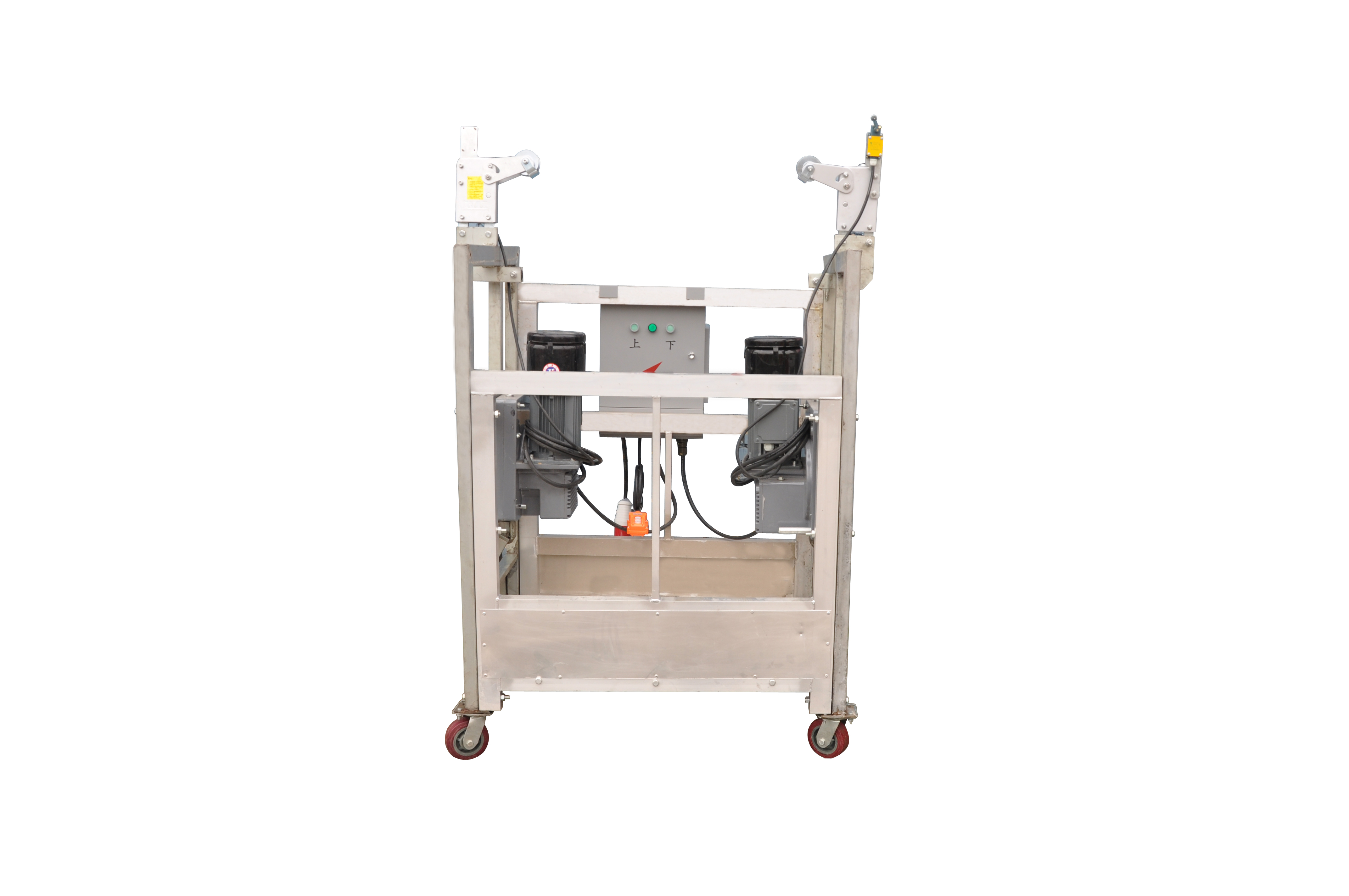

Suspended platforms are transforming modern construction and maintenance. These versatile tools provide safe, stable access to elevated areas. Compared to traditional scaffolding, suspended platforms offer improved safety, work efficiency, and cost-effectiveness. In this article, we will explore the key advantages of suspended platforms and their diverse applications. You'll learn why these platforms are increasingly becoming the preferred choice in various industries.

This table summarizes the key components of modern suspended platforms' built-in fall protection systems, which ensure safety when working at heights.

| Safety Component | Function | Application Scenarios | Technical Specifications | Efficiency and Effectiveness | Considerations |

|---|---|---|---|---|---|

| Fall Arrest Lock | Prevents platform from detaching or losing stability, ensuring secure operations at heights | High-rise building work, facade cleaning, maintenance | Can withstand 4 times the working load, complies with EN 1808 standards | Increases platform stability and reduces accident rates | Regularly check the lock for integrity to ensure correct locking mechanism |

| Emergency Braking System | Stops the platform movement immediately during failures or unexpected movements | Emergency stopping of platform, sudden halting during malfunction | Electromagnetic and centrifugal brake combination, response time under 3 seconds | Provides quick emergency response, maximizing worker safety | Inspect the braking system before each operation to ensure proper functionality |

| Safety Belt Attachment Points | Provides additional safety to prevent workers from falling | High-altitude work, lifting tasks, external wall repairs | Supports over 250 kg, complies with international safety standards | Enhances worker security, preventing falls from the platform | Inspect attachment points for stability and ensure all workers are properly equipped with safety belts |

| Anti-Tilt Mechanism | Prevents the platform from tilting due to uneven load or strong wind, keeping the platform steady | Facade cleaning, lifting operations, curtain wall installation | Maximum tilt angle limit of 5°, high stability in windy conditions | Ensures platform remains stable in adverse weather or uneven loading conditions | Check the anti-tilt mechanism during extreme weather conditions |

| Overload Protection | Automatically triggers alarms and shuts down the system if the platform exceeds safe load limits | High-load material transport, construction and industrial maintenance tasks | Smart load sensors monitor real-time weight, platform shuts down when overload occurs | Provides real-time monitoring, reduces risk of structural failure | Verify the load before each operation and calibrate the system accordingly |

Tip:Regular checks and maintenance of the fall arrest locks and emergency braking systems are crucial to ensure safety during high-rise operations.

Modern suspended platforms are equipped with smart load sensors that monitor the weight on the platform in real time. If the load exceeds the safe limit, the platform will automatically shut down to prevent accidents. This overload protection system ensures that platforms are never operated beyond their capacity, reducing the risk of structural failures. Such advanced monitoring features significantly improve worker security and are integral to reducing accidents on job sites.

Suspended platforms must comply with international safety regulations such as OSHA, EN 1808, and other local standards. These certifications ensure the platforms are reliable and meet the highest safety criteria for vertical access equipment. With regular inspections and maintenance, these platforms continue to perform within the safest operational limits, offering peace of mind to construction managers and workers alike.

This table compares the setup time, mobility, and coverage between traditional scaffolding and suspended platforms, helping project managers choose the more efficient solution for their needs.

| Feature | Traditional Scaffolding | Suspended Platform | Setup Time | Mobility | Work Area Coverage | Efficiency and Effectiveness | Considerations |

|---|---|---|---|---|---|---|---|

| Setup Time | 2-3 days | 2-3 hours | Long setup time, requires multiple workers | Quick installation, can be operated by one person | Limits the freedom of work area flexibility | Reduces downtime, allows faster project start-up | Ensure all platform components are ready and checked before installation |

| Mobility | Poor mobility, fixed after installation | Fully adjustable, can move vertically and horizontally along the building | Restricts access to fixed work areas | Flexible, can be adjusted to reach specific areas | Increases access to diverse areas of the building | Improves work efficiency, reduces time spent repositioning equipment | Check for mobility limitations during extreme weather or environmental conditions |

| Work Area Coverage | Fixed sections, frequent height adjustments needed | Continuous access, adjustable to any building height | Limited freedom of movement, requires material handling | Continuous access, no need to move platforms frequently | Increases accessibility to different parts of the building | Ensures uninterrupted workflow and access to all areas | Choose the right platform configuration based on project needs to avoid waste |

| Efficiency and Effectiveness | Fixed work area, low efficiency due to frequent repositioning | Provides efficient, uninterrupted work area access | Not suitable for dynamic work environments | High efficiency, enhances work flow and speed | Speeds up project completion times and ensures timely task completion | Evaluate the work environment and building structure, select the most suitable suspended platform configuration |

Tip:When choosing a suspended platform, consider the work area and mobility requirements of your project to maximize work efficiency and reduce project duration.

Suspended platforms are designed to move both vertically and horizontally, offering unparalleled flexibility in accessing different parts of a building or structure. Unlike scaffolding, which provides fixed access, these platforms can be adjusted to reach specific areas, even those that are difficult to access. This versatile movement capability allows workers to perform tasks such as window cleaning, facade repairs, or maintenance work without the need for additional equipment, enhancing both productivity and safety.

Traditional scaffolding often limits access to only fixed sections of a building, requiring workers to reposition it as the work progresses. Suspended platforms, on the other hand, provide continuous access to the work area. This uninterrupted access allows workers to move freely along the facade, improving workflow efficiency. Whether the task involves cleaning, painting, or installing glass panels, suspended platforms facilitate smooth operations without the need for frequent adjustments.

Suspended platforms offer significant cost savings compared to traditional scaffolding. The rapid setup and removal times reduce labor costs, while the reusable nature of the platforms eliminates the need for frequent material purchases. Additionally, suspended platforms require fewer materials to construct, minimizing waste. These savings are particularly evident in large-scale projects, where scaffolding can be costly and time-consuming to assemble and disassemble.

Suspended platforms are designed for long-term use. With proper maintenance, these platforms can last for years, offering exceptional durability. This makes them a more cost-effective solution for ongoing construction and maintenance projects. Unlike scaffolding, which is often discarded after use, suspended platforms can be reused across multiple projects, further enhancing their value and cost-effectiveness.

The advanced safety features of suspended platforms reduce the likelihood of workplace accidents. This enhanced safety not only protects workers but also lowers insurance premiums for companies that use these platforms. By minimizing the risk of accidents and injuries, suspended platforms contribute to a safer work environment, which in turn reduces the financial burden of insurance claims and liabilities for construction firms.

Suspended platforms are commonly used in the construction and maintenance of high-rise buildings. They provide easy access to exterior walls, allowing workers to perform tasks such as window washing, facade repairs, and painting. These platforms are particularly useful for skyscrapers, where traditional scaffolding may be impractical due to height and space constraints. By offering flexible, safe access to difficult-to-reach areas, suspended platforms have become an essential tool for high-rise building projects.

In industrial settings, suspended platforms are deployed for maintenance and inspections of large machinery, tanks, and silos. These platforms provide workers with safe access to elevated areas where traditional scaffolding would be cumbersome or impossible to use. Industries such as power plants, chemical facilities, and oil refineries rely on suspended platforms to perform critical tasks, including equipment repairs and structural maintenance at height.

Suspended platforms are also invaluable in bridge maintenance and inspection. These platforms allow workers to access the underside of bridges, inspect structural elements, and perform necessary repairs, all without the need for cumbersome scaffolding. The platforms' ability to adjust to different heights and configurations makes them ideal for bridge inspection projects, which often require quick deployment and flexibility in reaching difficult areas.

Unlike traditional scaffolding, suspended platforms occupy minimal ground space. This is particularly advantageous in urban environments where space is limited and construction projects must not disrupt surrounding areas. The compact design of suspended platforms allows construction work to continue without impeding pedestrian or vehicle traffic, making them a more sustainable option for city-based projects.

Many modern suspended platforms are powered by electricity, reducing emissions compared to diesel-powered equipment. These electric platforms help reduce the environmental impact of construction and maintenance projects by eliminating the need for fuel-burning machines. The shift towards electric-powered platforms aligns with the industry's growing emphasis on sustainability and reducing carbon footprints.

Suspended platforms are built to last and can be used repeatedly across various projects. Their durability and reusability help minimize material waste, making them a more eco-friendly option than scaffolding, which is often discarded after use. Additionally, the energy-efficient motors used in many suspended platforms consume less power, further contributing to reduced environmental impact and cost savings for construction firms.

The future of suspended platforms is closely tied to advancements in technology. IoT-enabled platforms can now offer real-time monitoring of load capacity, movement, and operational status. These smart platforms can alert operators to potential issues before they become problems, improving safety and operational efficiency. As technology continues to evolve, we can expect even more advanced features to be integrated into suspended platforms, further enhancing their functionality.

Suspended platforms are increasingly being customized to meet the specific needs of different construction projects. Whether it's a high-rise building, a bridge, or an industrial facility, platforms can be tailored to suit the project's unique requirements. Custom configurations allow for greater flexibility, making suspended platforms adaptable to a wide range of applications across various industries.

As the construction industry continues to prioritize safety, efficiency, and cost-effectiveness, the adoption of suspended platforms is expected to increase globally. These platforms offer clear advantages over traditional scaffolding, and their use is growing in regions with significant construction activity. With their proven benefits, suspended platforms are becoming a standard tool in modern construction and maintenance operations worldwide.

Suspended platforms offer significant advantages over traditional scaffolding in terms of safety, efficiency, and cost-effectiveness. Their versatility in providing continuous access to elevated areas makes them essential for high-rise construction, industrial maintenance, and bridge inspections. With technological advancements and a focus on sustainability, suspended platforms are becoming increasingly vital in modern construction. Companies like Nantong Haibao Construction Machinery Co., Ltd. provide innovative suspended platforms that offer unparalleled value, helping contractors boost productivity while ensuring the safety of their workers.

A: A suspended platform, also known as a swing stage, is a temporary platform suspended from a building or structure. It is used to provide safe access for workers to elevated areas for tasks such as cleaning, maintenance, or construction.

A: Suspended platforms offer faster setup and greater flexibility compared to traditional scaffolding. Their ability to move both vertically and horizontally allows workers to easily access different parts of a building, improving overall work efficiency.

A: Suspended platforms are more versatile and cost-effective than scaffolding. They offer continuous access to work areas, require less setup time, and improve safety with built-in fall protection and load monitoring systems.

A: Suspended platforms are equipped with fall protection systems, emergency brakes, overload protection, and compliance with international safety standards, ensuring worker safety while working at heights.

A: Yes, Suspended Platforms save on labor and material costs due to their fast setup and reusable nature. They are particularly advantageous for large-scale projects, where traditional scaffolding can be costly and time-consuming.

A: With proper maintenance, Suspended Platforms can be used for many years. Their durable design allows them to be reused across multiple projects, making them a long-term cost-effective solution for construction and maintenance tasks.